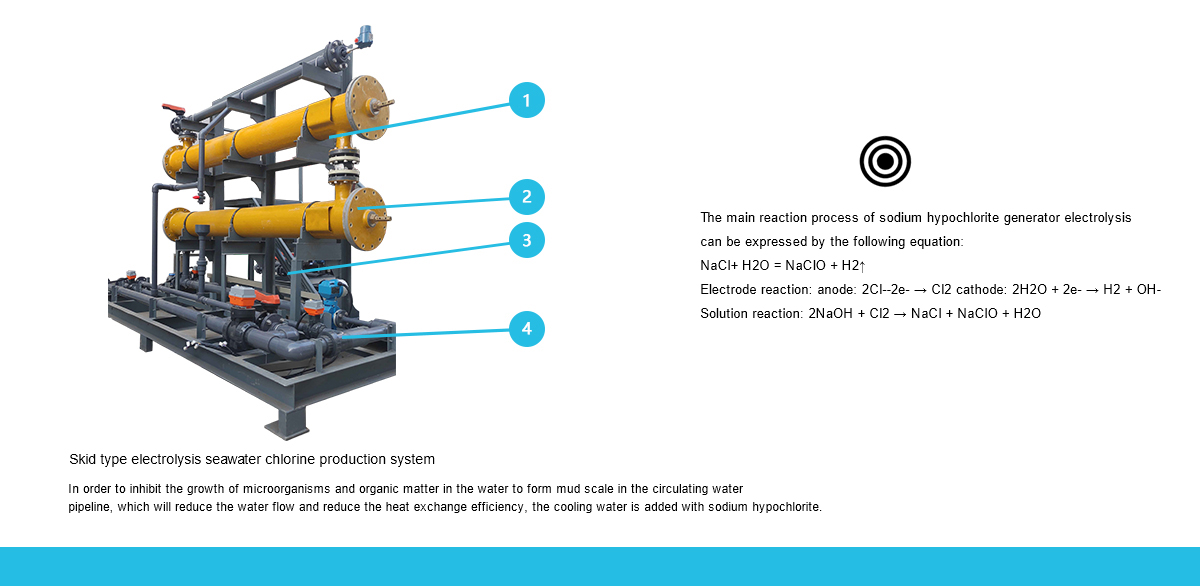

Products >> Sodium_Hypochlorite_Generator (Seawater) >> skid mounted electrolysis seawater chlorine production system

Features:

seawater electrolysis technology

compact and reasonable structure

energy-saving operation

convenient operation and maintenance

high operational reliability

long equipment life

ISO, CE

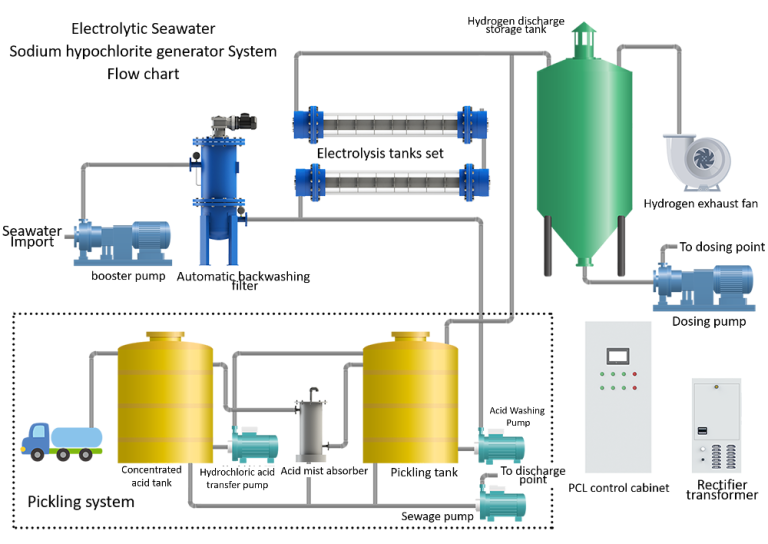

The electrolytic seawater sodium hypochlorite generator uses natural seawater and adopts high-speed electrolysis to prepare high-activity sodium hypochlorite solution on site. The sodium hypochlorite solution is transported to the dosing point as a biocide through dehydrogenation storage, effectively killing microorganisms, sea creatures, algae, and crustaceans in the water body, and preventing the blockage of circulating water pipelines and condenser systems.

The main reaction process of sodium hypochlorite generator electrolysis can be expressed by the following equation:

NaCl+ H2O = NaClO + H2↑

Electrode reaction: anode: 2Cl--2e- → Cl2 cathode: 2H2O + 2e- → H2 + OH-

Solution reaction: 2NaOH + Cl2 → NaCl + NaClO + H2O

System composition:

Application areas:

Technical Parameters

Products Category

- Hydrochloric acid production line

- Sodium_Hypochlorite_Generator (Seawater)

- Sodium_Hypochlorite_Generator (Salt Water)

- 15% Sodium_Hypochlorite_Plant

- Ozone Generator

- Strong Alkaline Water generator Machine china

- on site chlorine gas generator china

- Chlorine_Dioxide_Generator

- Chlorine Liquefaction Refill Cylinder Line

- UV sterilization

- Seawater Electro Chlorination System Package China UAE desalination

- Automatic dosing system PAC PAM

- Reverse_osmosis_RO_system seawater desalination system

- Online Chlorine Concentration Meter Gauge

- Sodium Hydroxide Generator detergent caustic soda plant NaOH

- Chlor-alkali plant membrane electrolysis

- Hypochlorous Acid Anolyte Generator

- Medical grade Neutral Anolyte HOCL Generator

- Alkaline ionized water machine

Contact Us

Name: Diana

Tel: +86-15201328666

Mobile: +86-15201328666

E-mail: info@bluewaVv.com

Skype: +86-15201328666

WeChat: +8615201328666

Whatsapp: +8615201328666

Add: Office N.420D-C1 Tower Ajman,UAE

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry